Compressed Air Cooling Solutions

Standard and Custom Aftercoolers

Compressed air cooling is essential for maintaining the efficiency and longevity of industrial air systems. Our aftercoolers are designed to remove heat and moisture from compressed air, ensuring the best performance for your equipment. We partner with you to deliver cost-effective, high-performance compressed air cooling solutions tailored to your needs.

- Air-Cooled Aftercoolers: Cool compressed air using ambient air, ideal for water-scarce environments.

- Moisture Separators: Remove water from cooled air after leaving the aftercooler.

- Water-Cooled Aftercoolers: Use water for high-efficiency compressed air cooling in stationary setups.

- Durable Materials: Copper tubes and steel shells, with optional CuNi for corrosive environments.

- High Performance: Standard units with ratings up to 250 PSI and temperatures up to 350°F.

- Custom Aftercoolers: Tailored solutions for specific industrial compressed air cooling requirements.

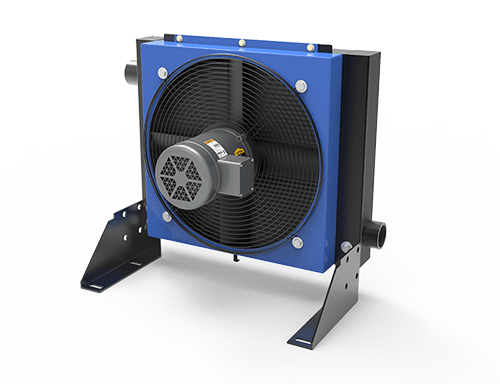

Air-Cooled Aftercoolers:

Efficient cooling for compressed air systems

- AC and DC Units Available

- Cooling Using Ambient Air

- Wide Range of Flows

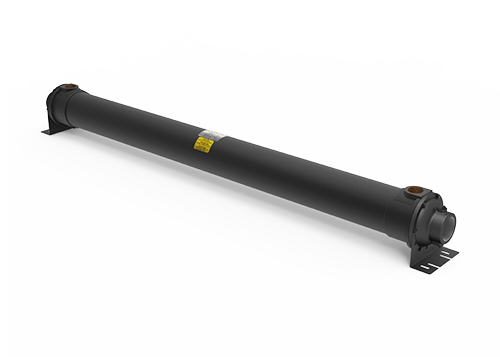

Water-Cooled Aftercoolers:

High-efficiency compressed air cooling

- Shell & Tube Designs

- Standard and Custom Solutions

- High Flow Units Available

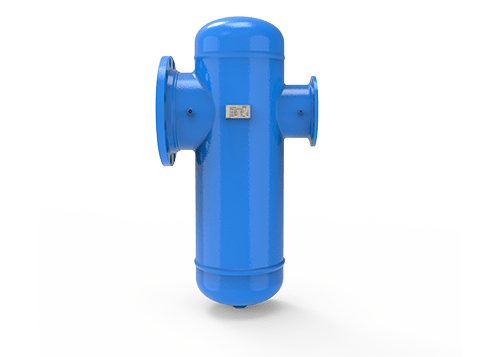

Moisture Separators:

Enhance compressed air quality

- Exceptional Moisture Removal

- Ideal For All Applications

- Wide Range of CFM Ratings

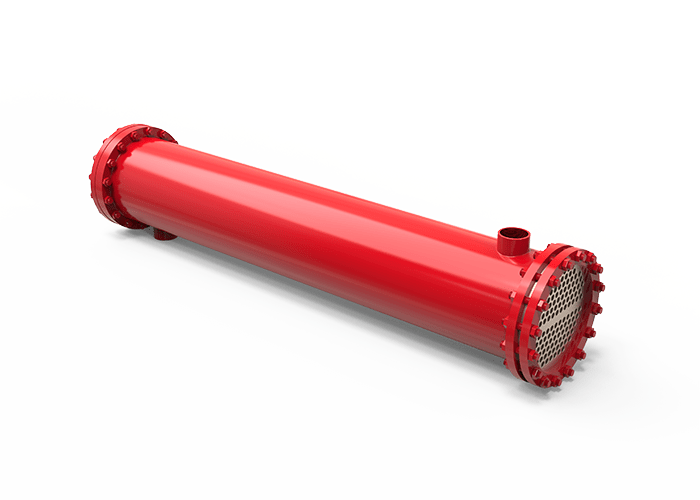

Custom Aftercoolers:

Tailored compressed air cooling solutions

- High PSI and Temperatures

- Custom Materials Available

- Specialized Industries

Compressed Air Cooling Solutions

Since our inception, we've focused on providing top-tier compressed air cooling solutions, specializing in air-cooled and water-cooled aftercoolers critical for industrial and mobile applications. Our expert engineers will guide you through selecting the most suitable aftercooler type for your application.

Each aftercooler is engineered to ensure efficient heat and moisture removal from compressed air, protecting equipment and enhancing system performance. Air-cooled aftercoolers are ideal for locations lacking a water source, while water-cooled systems offer high-efficiency cooling for stationary setups. Custom aftercoolers are tailored for specialized applications.

We offer both standard and custom-engineered compressed air cooling solutions at competitive prices. Our mission is to support you from sizing and selection to installation, ensuring your aftercooler exceeds expectations.